Product Description

#404 High Density Adhesive Filler (404-15)

Model # 382895

LOWEST PRICES GUARANTEED

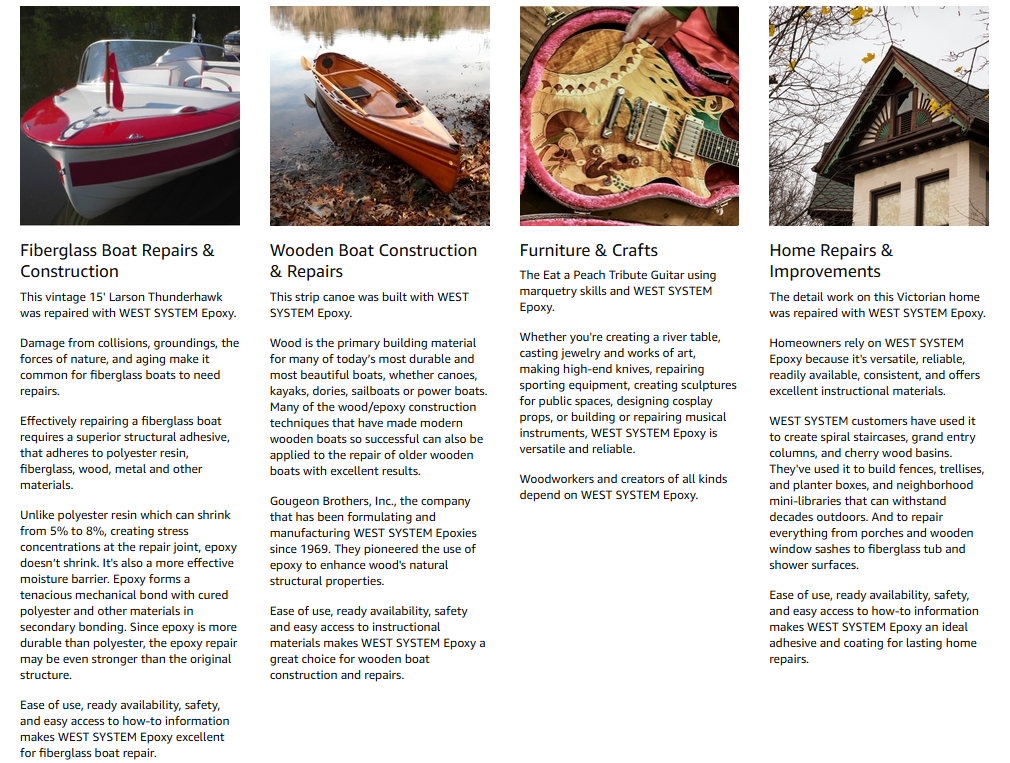

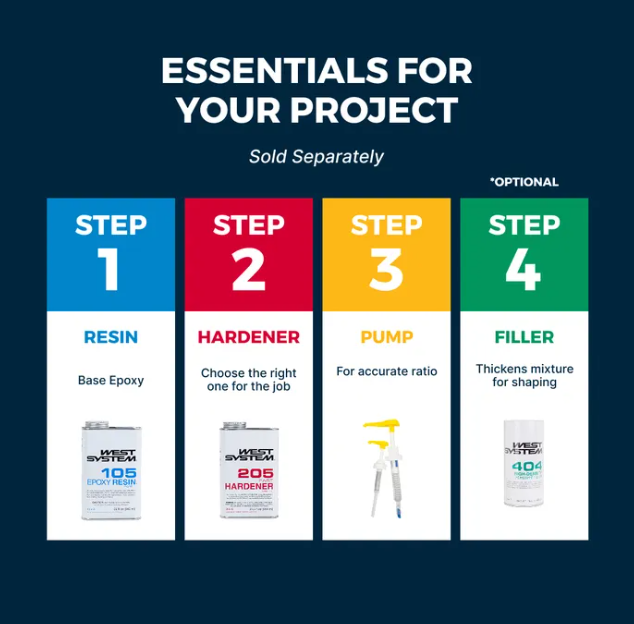

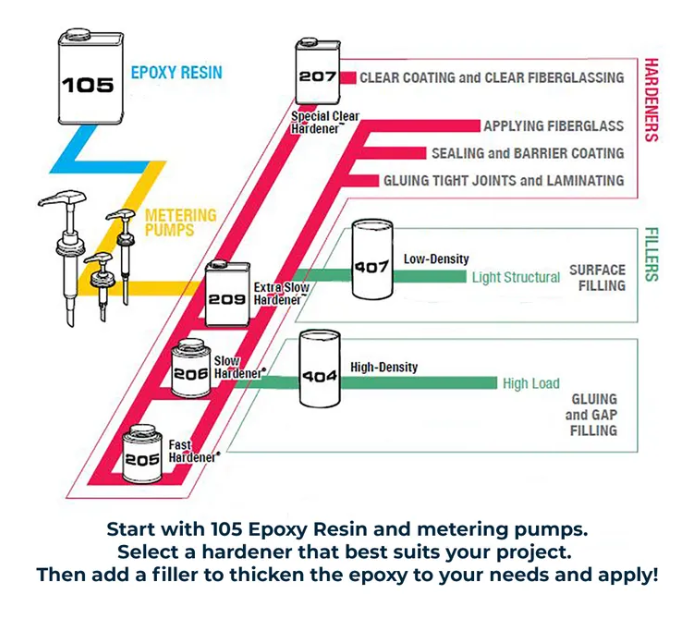

Available fillers and additives give you the ability to customize WEST SYSTEM 105 Epoxy Resin for your specific application.

404 High-Density Adhesive Filler is an epoxy thickening additive. We developed it for maximum physical adhesive properties in hardware bonding, or anywhere that high-cyclic loads are anticipated.

Blended with epoxy, it makes an excellent gap filler or structural fillets. Use this filler wherever you need an especially strong bond. You can blend it into any WEST SYSTEM® 105 Epoxy Resin®/200 Series Hardener combination, G/flex® 650, or G/5® Five-Minute Adhesive.

DESIGNED FOR

- Wood Bonding

- Adhesion

- Gap Filling

- Fastener Bonding

SIZES

- 404-15 (15.2 oz)

- 404-45 (43 oz)

- 404-B (30 lb)

PROJECT USES

Thicken epoxy blended resin/hardener and create a multi-purpose adhesive for:

- Marine

- Boat Repair

- Hardware Bonding

- Coating

- Wood Fillets

SPECIFICS

- Color | Off-White

- Cures to off-white color

- Fine fiber powder

- Weight: 15.2 ounces

INCLUDES

- (1) 15.2 oz Filler

All other WEST SYSTEM products are sold separately.

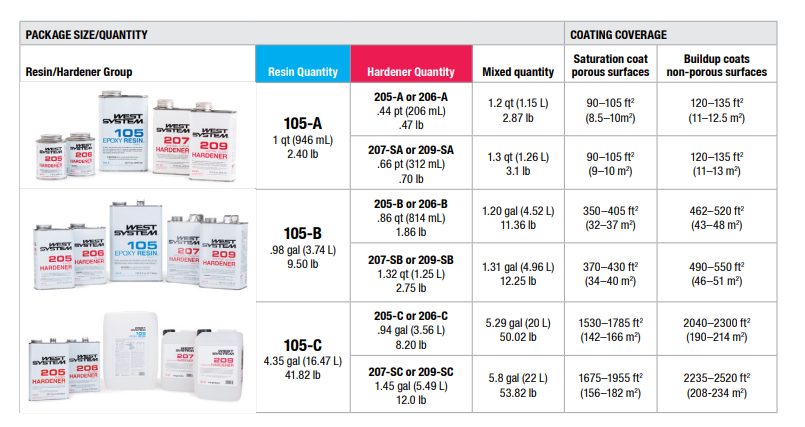

For the suitability of fillers for specific applications, see the Filler Selection Chart.

For more about 105 Epoxy Resin and the complete line of WEST SYSTEM products, see the Product Selection Guide.

Additional Info:

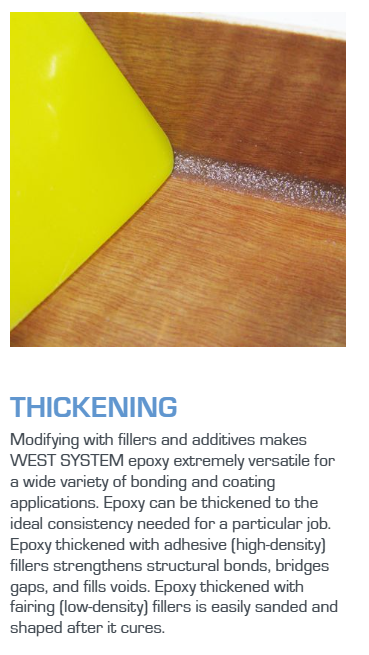

Adhesive Fillers vs. Fairing Fillers

WEST SYSTEM® fillers are used to thicken the basic epoxy resin/hardener mixture for specific applications. Each filler possesses a unique set of physical characteristics, but they can be generally categorized as either Adhesive (high-density) or Fairing (low-density). Adhesive filler mixed with epoxy cures to a strong, hard-to-sand plastic useful in structural epoxy applications like bonding, filleting, and hardware bonding. Fairing filler mixed with epoxy cures to light, easily sandable material that is generally used for cosmetic or surface applications like shaping, filling, or fairing.

Epoxy Fillers and Epoxy Strength

While certain fillers will increase the density of epoxy, this does not correlate to higher physical properties or increased adhesion strength. Epoxy is strongest without filler added to it, but adhesive fillers are excellent for increasing the viscosity of the epoxy mixture, bridging gaps, preventing the epoxy from soaking too far into the wood and preventing glue-starved joints. Fairing fillers turn the epoxy into an easily sanded fairing compound.

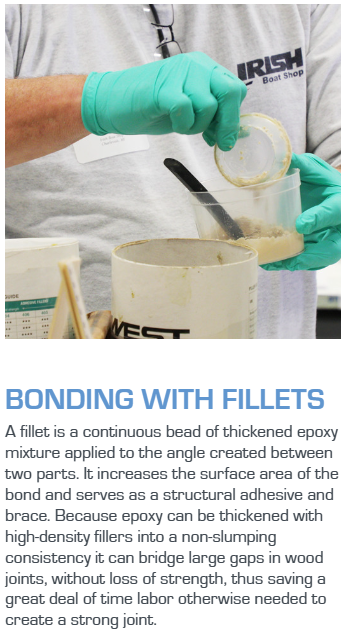

Bonding with Fillets

Gluing plywood structures together with epoxy fillets saves considerable time constructing the joints and reduces the overall weight of the structure compared to more traditional methods using wooden cleats and screws. The strength and gap-filling qualities of epoxy eliminate the need for precisely fitted wood cleats that otherwise require time and skill to create. When gluing with conventional adhesives, that are non-gap filling such as resorcinol glue, wood cleats need to be well fitted, need to be wide enough to provide sufficient glued surface area, and provide enough thickness for screws to be driven into. Building with epoxy fillets is especially beneficial when attaching bulkheads to hull sides, attaching hull sides to hull bottoms where the faces of the plywood are coming together at ever-changing angles.

Filling Wood Gaps

When you use adhesive fillers, or high-density fillers, to thicken epoxy to a [non-slumping consistency] it can bridge large gaps in wood joints, without loss of strength, thus saving a great deal of time labor otherwise needed to create a strong joint.

Filler Recipes

If your project calls for several batches of the same thickened epoxy, it is best to come up with a recipe. So much epoxy and so much filler per batch. Add measured amounts to the first batch until the viscosity suits your specific need, keeping track of the total amount added. For the remaining batches, all of the filler can be added at once, and the batches will be consistent in viscosity. The WEST SYSTEM User Manual & Product Guide can help you come up with a mix recipe. Check the Filler Guide to find out how much filler to blend into the mixed epoxy to achieve a given consistency. This guide includes recommendations for a variety of viscosities for each of our fillers. Keep in mind that it is just a guide. It’s a good idea to thicken the first batch in stages.

Shop with Confidence! Official WEST SYSTEM Dealer

- Guaranteed Authentic Products

- Factory-Fresh Inventory

- Backed by Manufacturer Support

Not sure if we have this in stock? Call to check availability or use the Chat below!

TOP TESTIMONIALS

Safe payment on our website

- Choosing a selection results in a full page refresh.

- Opens in a new window.