Product Description

#105 Part 1 Epoxy Resin, 4.3 Gallons (105-C)

Model # 323725

FREE Shipping

LOWEST PRICES GUARANTEED

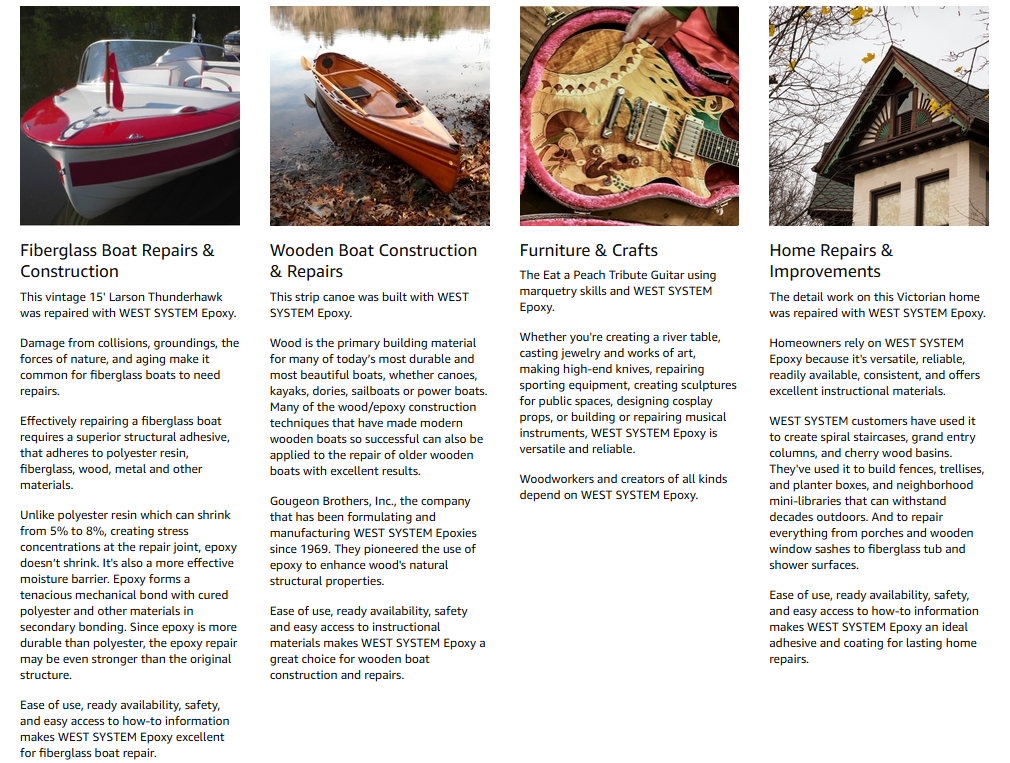

WEST SYSTEM #105-A Epoxy Resin: The Ultimate Choice for Boat Building and Repair

105 Epoxy Resin® is a clear, low-viscosity liquid epoxy resin. Formulated for use with one of four WEST SYSTEM® hardeners. It can be cured in a wide temperature range to form a high-strength solid bond with excellent moisture resistance. 105 Epoxy Resin, when mixed at the proper ratio with a WEST SYSTEM hardener, is an excellent adhesive.

Upgrade your boat repair and construction projects with WEST SYSTEM #105-C Epoxy Resin—trusted for its exceptional quality and performance in the marine industry.

DESIGNED FOR

- Wood bonding

- Fiberglass

- Reinforcing fabrics

- Composite materials

- Variety of metals

DETAILS

- Best Use: Formulated Specifically to Waterproof and Bond Wood, Fiberglass and Metals

- Capacity: 1 Quart

- Color: Clear Amber

- Cure Time: Variable

- Type: Two-Part Epoxy Resin

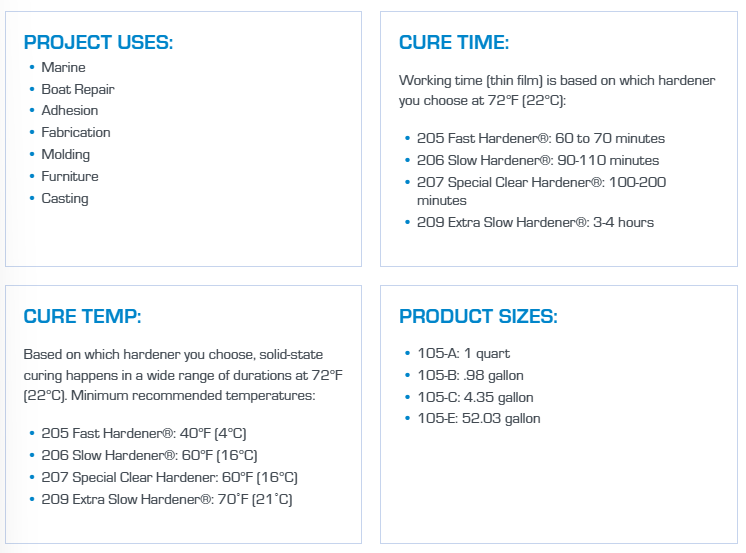

PROJECT USES

- Marine

- Boat Repair

- Adhesion

- Fabrication

- Molding

- Furniture

- Casting

CURE TIME

Working time (thin film) is based on which hardener you choose at 72°F (22°C):

- 205 Fast Hardener®: 60 to 70 minutes

- 206 Slow Hardener®: 90-110 minutes

- 207 Special Clear Hardener®: 100-200 minutes

- 209 Extra Slow Hardener®: 3-4 hours

CURE TEMP

Based on which hardener you choose, solid-state curing happens in a wide range of durations at 72°F (22°C). Minimum recommended temperatures:

- 205 Fast Hardener®: 40°F (4°C)

- 206 Slow Hardener®: 60°F (16°C)

- 207 Special Clear Hardener: 60°F (16°C)

- 209 Extra Slow Hardener®: 70˚F (21˚C)

SIZES

- 1qt. (105-A)

- 0.98 gallon (105-B)

- 4.3 Gallons (105-C)

- 52 Gallons (105-E

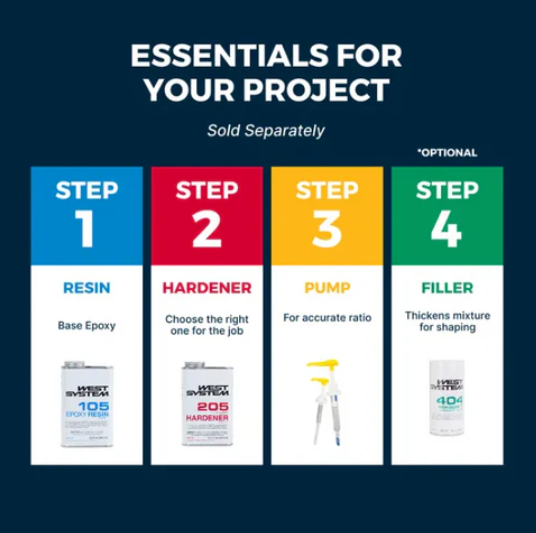

INCLUDES

- (1) 4.3 Gallon Epoxy Resin

All other WEST SYSTEM products are sold separately.

For the suitability of fillers for specific applications, see the Filler Selection Chart.

For more about 105 Epoxy Resin and the complete line of WEST SYSTEM products, see the Product Selection Guide.

Additional Info:

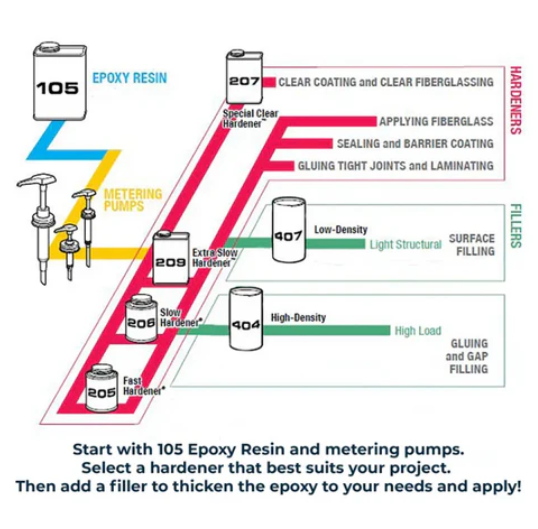

Choosing the Right Epoxy System

WEST SYSTEM® 105 Epoxy Resin® is a professional quality, two-part epoxy system developed for high strength and good versatility. The Epoxy Selection Guide is a handy tool to help you pair 105 Epoxy Resin with a choice of four hardeners to best match your working temperatures, desired cure speed, and coating clarity. Epoxy System Selection Guide

Estimating Coverage for Fabric Application

Estimating how much epoxy is required to wet out fabric is based on the fabric weight and square footage. We provide estimates of the amount of epoxy needed to apply 1 sq. ft. of fiberglass cloth. Estimate Coverage

Estimating how much epoxy is required to wet out fabric is based on the fabric weight and square footage. We provide estimates of the amount of epoxy needed to apply 1 sq. ft. of fiberglass cloth. Estimate Coverage with images below.

Coating

105 Epoxy Resin is a great coating material. Applied with a roller, it offers excellent thin-film characteristics. It will flow out and self-level without “fisheyeing.” By combining it with blush-free 207 Special Clear Hardener, you can create a natural finish. You’ll just need to add a couple of coats of varnish for UV protection. This is a good alternative that builds mil thickness quickly, saving time and effort. The results are long-lasting. 105 Resin’s viscosity is approximately 1000 centipoise (cp) at 72 F (22C). Pair 105 Epoxy with corresponding letter size of 205 Fast Hardener, 206 Slow Hardener, 209 Extra Slow Hardener or 207 Special Clear Hardener.

Filler and Epoxy Strength

WEST SYSTEM Epoxy fillers are used to thicken the basic epoxy resin/hardener mixture for specific applications. Adding these filling agents to blended epoxy resin and hardener allows you to control the consistency of the epoxy, bridge gaps in joints, create either strong or sandable fillets with epoxy, or alter the cured density of epoxy making it easier to sand smooth.

Additives and Pigments

Additives and Pigments are blended into mixed epoxy to enhance specific physical properties or alter the color or opacity. Additives improve epoxy’s abrasion resistance or moisture resistance.

Epoxy Techniques

We believe every builder or repairer should develop an understanding of 105 Epoxy and a feel for working with it. We strongly recommend performing simple “shop floor” tests as you proceed. The 105 Epoxy System was designed to give you the flexibility to tailor the epoxy to meet the demands of your project and work environment. If you’re just starting out, familiarize yourself with our recommended epoxy techniques. When you understand the working and cured characteristics of your 105 Epoxy blends, you’ll come up with the best solutions to construction and repair problems.

Instruction Manuals

Gougeon Brothers, Inc. offers a range of detailed epoxy instruction manuals to help you get started with WEST SYSTEM Epoxy products. All of our print publications are available as free downloads. Download Instruction Manuals

Metering Pumps

For group sizes "A", "B" and "C", 205 and 206 Hardeners are mixed with 105 Epoxy Resin in a ratio of 5:1. 207 and 209 Hardeners are mixed with 105 Epoxy Resin in a ratio of 3:1. To make sure you get the proportions right, we highly recommend purchase of the 300 Mini-Pump Kit, which meters the hardener and resin in the exact proportions you need. For group size "E" and larger sizes, we suggest use of either the 306-23 Special Purpose Resin/Hardener pump (Model 128845), which dispenses hardener and 105 Epoxy Resin at a ratio of 3:1, or the 306-25 Special Purpose Resin/Hardener pump (Model 335703), which dispenses hardener and 105 Epoxy Resin at a ratio of 5:1.

Epoxy Shelf Life & Proper Storage

WEST SYSTEM resins and hardeners do not have a strict shelf life. Certain changes may make them less effective for some jobs, but the resin and hardener will still be reactive. Because we are an ISO 9001 company, lot numbers are provided on containers and we keep retains of every batch of hardener we make up to 2 years from the date of manufacturing, and resins for 3 years. However, the actual shelf life is typically far longer.

Shop with Confidence! Official WEST SYSTEM Dealer

- Guaranteed Authentic Products

- Factory-Fresh Inventory

- Backed by Manufacturer Support

Not sure if we have this in stock? Call to check availability or use the Chat below!

TOP TESTIMONIALS

Safe payment on our website

- Choosing a selection results in a full page refresh.

- Opens in a new window.