Product Description

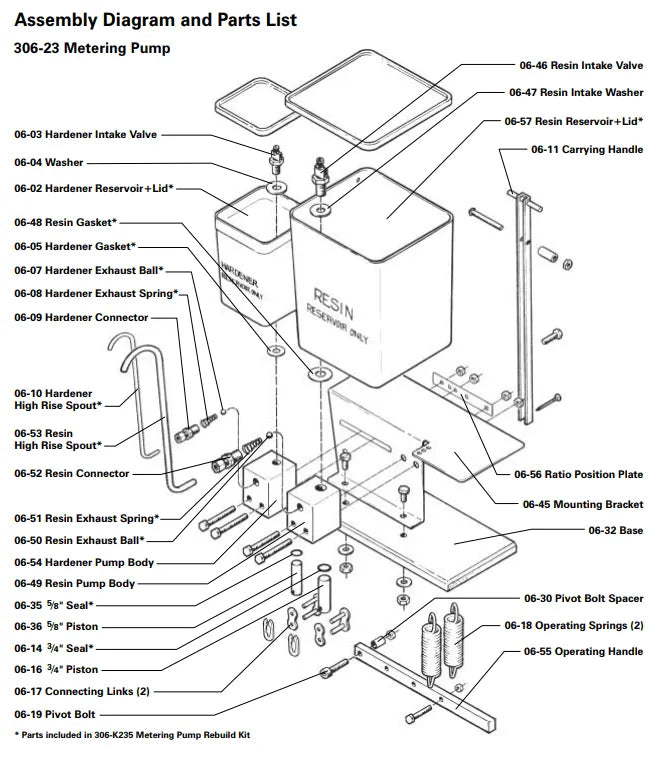

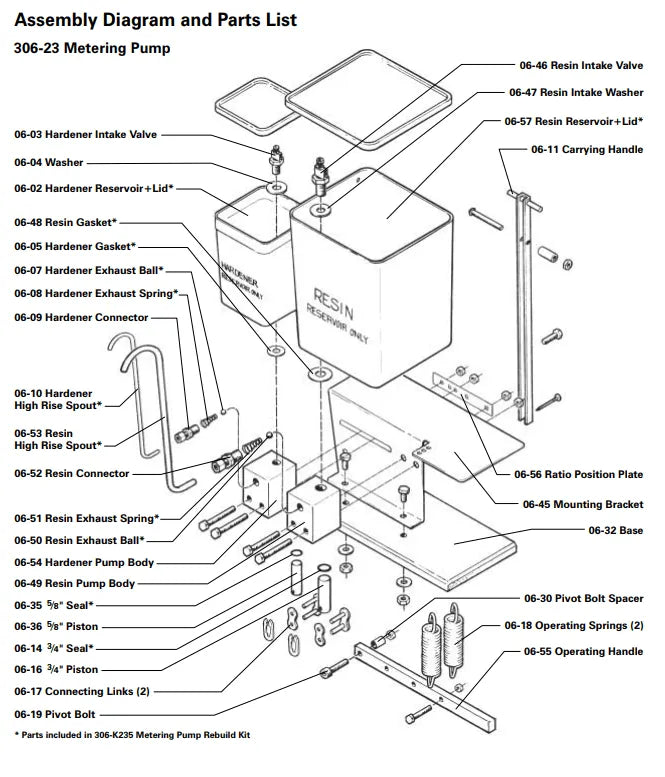

3:1 Ratio Model-A Metering Pump (306-23)

Model # 128845

FREE Shipping

LOWEST PRICES GUARANTEED

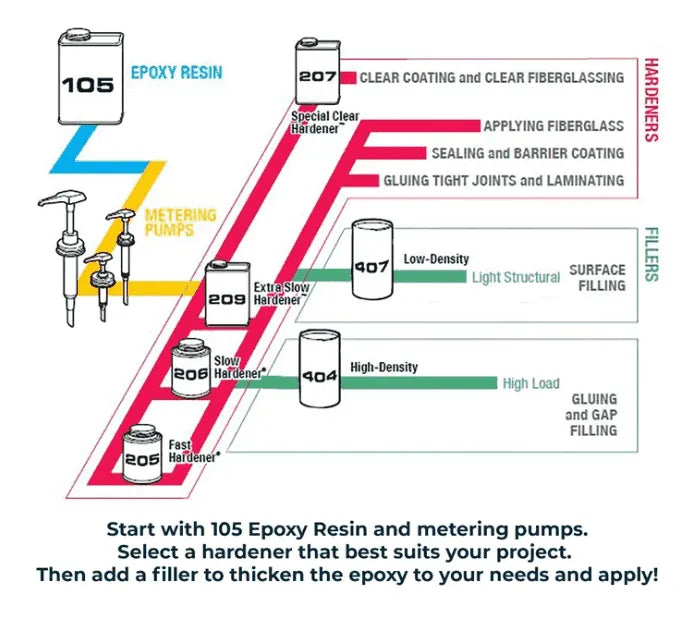

For metering larger quantities of 105 Epoxy Resin and 207 Special Clear Hardener or 209 Extra Slow Hardener. (3:1 Ratio)

Also available in a 5:1 Metering Pump Ratio

The 306-23 Model-A Metering Pump will reduce mixing time and waste on large projects. A carrying handle allows you to move the pump to where the work is. Reservoirs hold one gallon of resin and one quart of hardener. Dispenses approximately 0.5 fl. oz. of resin-hardener per pump stroke, or about 1 quart per minute.

DESIGNED FOR

SPECIFICS

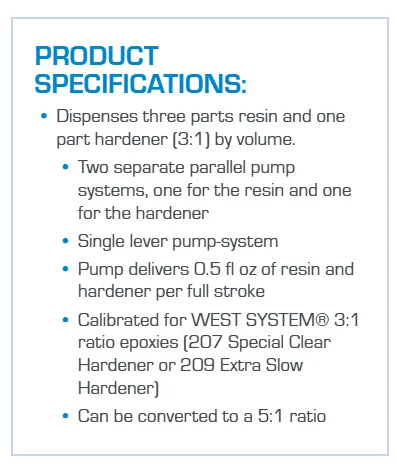

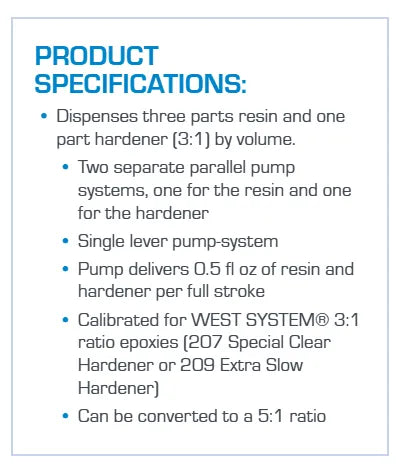

- Dispenses three parts resin and one part hardener (3:1) by volume.

- Two separate parallel pump systems, one for the resin and one for the hardener

- Single lever pump-system

- Pump delivers 0.5 fl oz of resin and hardener per full stroke

- Calibrated for WEST SYSTEM® 3:1 ratio epoxies (207 Special Clear Hardener or 209 Extra Slow Hardener)

- Can be converted to a 5:1 ratio

PRODUCT USES

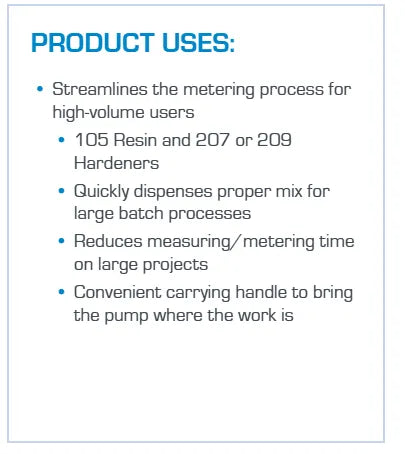

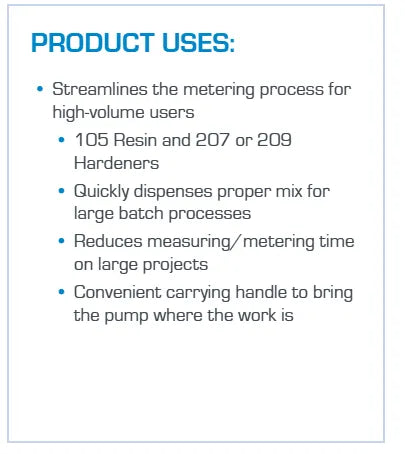

- Streamlines the metering process for high-volume users

- 105 Resin and 207 or 209 Hardeners

- Quickly dispenses proper mix for large batch processes

- Reduces measuring/metering time on large projects

- Convenient carrying handle to bring the pump where the work is

INCLUDES

- (1) 3:1 Ratio Metering Pump

All other WEST SYSTEM products are sold separately.

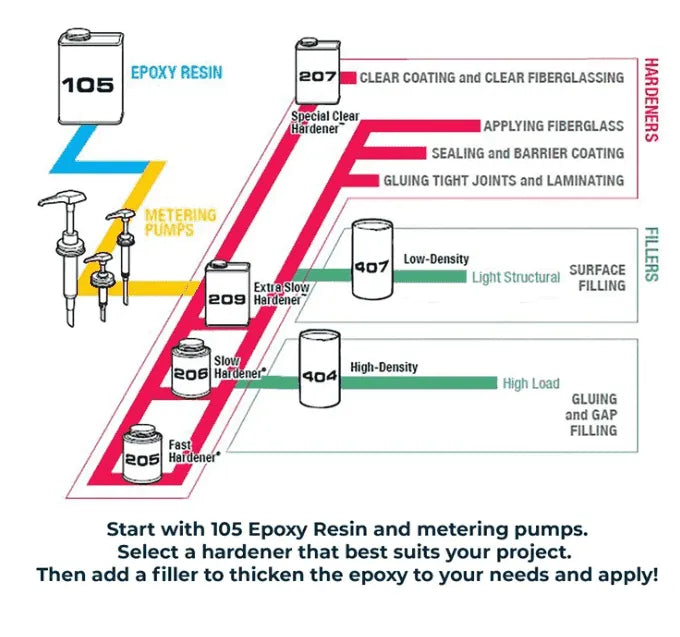

For the suitability of fillers for specific applications, see the Filler Selection Chart.

For more about 105 Epoxy Resin and the complete line of WEST SYSTEM products, see the Product Selection Guide.

Additional Info:

Priming 306-23 Metering Pump

- CAUTION—Remove all materials from Resin and Hardener reservoirs and be sure the reservoirs are clean before filling.

- Prime the hardener system first. Fill the hardener reservoir with hardener. Pump the operating handle until the hardener flows evenly from the spout without emitting air. Ten to twenty strokes of the handle should produce hardener at the spout. If not, use a stick or dowel to hold down the intake valve screw head inside the reservoir while slowly pumping the handle. This will allow trapped air to escape the valve and hardener to reach the piston.

- After the hardener side is working properly, fill the resin reservoir and prime the resin system. Dispense the resin and hardener into separate, clean containers, or the original resin and hardener cans. After both systems are working, return the dispensed resin and hardener to the proper reservoirs.

- Note: When filling the reservoirs do not get any resin in the hardener reservoir, or hardener in the resin reservoir. Always keep one reservoir covered while filling the other. Keep reservoirs covered at all other times to prevent contamination. Once primed, the pump should not be allowed to dry out. Dried hardener can damage the piston seal and clog the passages and valves. For this reason, the ratio is not checked at the factory.

Ratio Verification with 306-23 Metering Pump

WARNING! Check the ratio of resin to hardener dispensed by the pump before using the epoxy on your project. Recheck the ratio periodically or if you later experience incomplete or unusually fast or slow curing.

By weight

The most accurate method of checking the ratio is by weight. Dispense at least five strokes of resin and hardener into separate, pre-weighed containers. Weigh each of the samples on a balance or gram scale to determine the net weight of each. Divide the net weight of the resin by the net weight of the hardener to find the ratio of resin to hardener. The ideal or target ratio and the acceptable ratio ranges for each resin/hardener combination are shown in the charts below. Deviations beyond the acceptable range in either direction will result in an incomplete cure and significant weakening of the epoxy.

By volume

The ratio can also be checked by volume. Pump at least five strokes of resin and hardener separately into the two graduated measuring cups included with the pump. Set the cups on a level surface to accurately determine the volume of resin and hardener, in either ounces or milliliters. Divide the volume of resin by the volume of hardener. The ideal or target ratio and the acceptable ratio range is shown in the chart below. The ratio by volume is different than the ratio by weight because hardener has a lower density (greater volume per unit of weight) than resin. This check can be done with any two identical, narrow, cylindrical containers. Measure the levels of the dispensed resin and hardener in the containers with a ruler. Divide the measured height of the resin by the measured height of the hardener to find the ratio. Monitor the resin/hardener ratio by examining cured epoxy left in mixing cups. If the residue is not sufficiently hard after the appropriate cure time has passed, recheck the pump ratio.

Acceptable ratio ranges for WEST SYSTEM 3:1 ratio Resin and Hardeners (207 & 209) with the 306-23 Epoxy Metering Pump:

Mixing with Drill Motor Mixers

A variety of motor-driven mixers can be used to thoroughly mix epoxy. They are essentially paint mixers or variations of paint mixers chucked into a variable speed drill. When mixing with a motorized mixer, we recommend the following three-step approach:

- Mix for 30 seconds with a drill motor mixer.

- Stir by hand with the measuring stick, thoroughly scraping the corners and sides.

- Mix for 15 to 30 seconds more to blend completely.

Quality Control

Before mixing that big batch, consider quality control. Resin and hardener must be thoroughly mixed. We all know this but tend to forget during big projects when we’re pressed for time. This is not the place to look for shortcuts. If you don’t follow certain guidelines, a fancy electric mixer will not make up for it.

Shop with Confidence! Official WEST SYSTEM Dealer

- Guaranteed Authentic Products

- Factory-Fresh Inventory

- Backed by Manufacturer Support

WARNING: This product can expose you to chemicals which are known to the State of California to cause cancer, birth defects or other reproductive harm. For more information go to P65Warnings.ca.gov.

Safe payment on our website

- Choosing a selection results in a full page refresh.

- Opens in a new window.