Product Description

WEST SYSTEM G/Flex #650 Aluminum Boat Repair Kit (650-K)

Model # 9223140

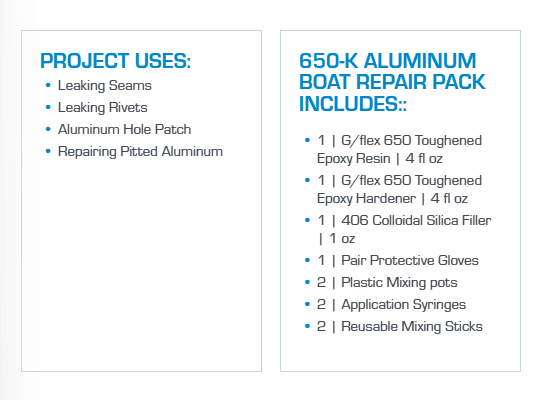

Repair the most common problems with aluminum boats and canoes: leaking seams and rivets in aluminum boats with the Aluminum Boat Repair Kit. Each kit contains 8 ounces of G/flex® 650 Toughened Epoxy, adhesive filler, application syringes, mixing cups and reusable mixing sticks, and protective gloves. Illustrated, detailed instructions explain how to repair leaking seams and rivets in aluminum boats. All components are contained in a sturdy, resealable package. (650K)

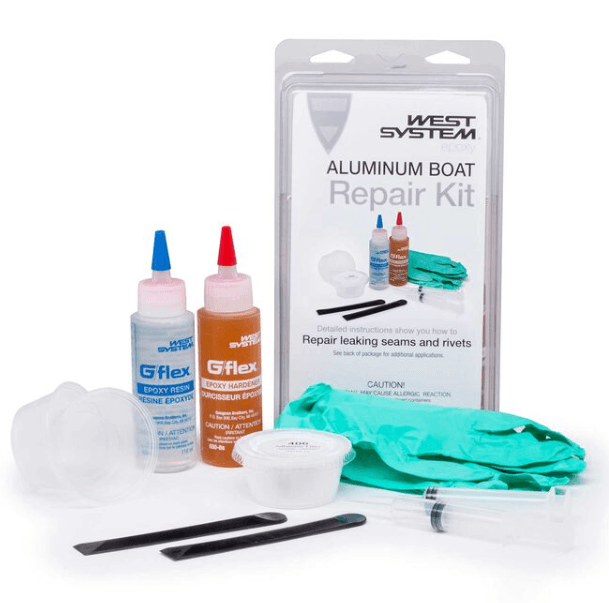

PROJECT USES

- Leaking Seams

- Leaking Rivets

- Aluminum Hole Patch

- Repairing Pitted Aluminum

INCLUDES

- 1 G/flex 650 Toughened Epoxy Resin | 4 fl oz

- 1 G/flex 650 Toughened Epoxy Hardener | 4 fl oz

- 1 406 Colloidal Silica Filler | 1 oz

- 1 Pair Protective Gloves

- 2 Plastic Mixing pots

- 2 Application Syringes

- 2 Reusable Mixing Sticks

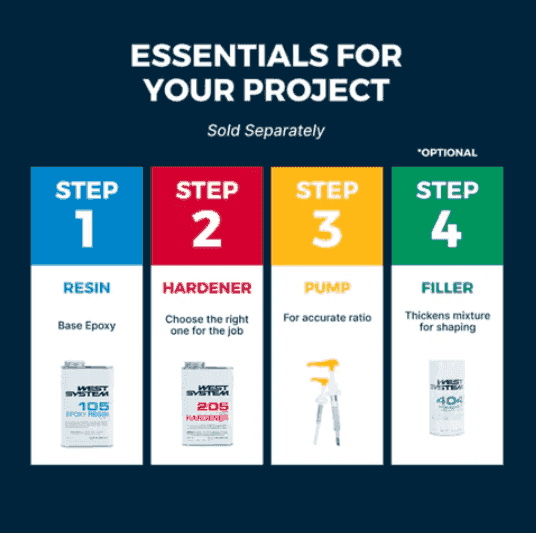

All other WEST SYSTEM products are sold separately.

For the suitability of fillers for specific applications, see the Filler Selection Chart.

For more about the complete line of WEST SYSTEM products, see the Product Selection Guide.

Additional Info:

A Toughened Epoxy That's Flexible

G/flex is toughened. This allows it to make structural bonds that can absorb the stresses of expansion, contraction, shock, and vibration. This epoxy is resilient and impact resistant. With a modulus of elasticity of 150,000 psi (WEST SYSTEM® 105 Epoxy Resin®/205 Fast Hardener® has a modulus of elasticity of 450,000 psi), G/flex is more flexible and can deflect further before breaking than WEST SYSTEM 105/205 while being much stiffer than typical adhesive sealants.

G/flex & Wet Surfaces

G/flex has the ability to glue damp woods. It can be used on wet surfaces, even underwater when applied with specific techniques.

Fix Leaking Rivets in Aluminum Boats

- Fill the inside with water up to the waterline

- Identify and mark leaks

- Flip the boat over for easier access to the bottom and prepare the surface for bonding

- Clean out any debris that might still be stuck inside. On the rivets, use a wire brush in a circular motion to abrade the surface

- Mix the G/flex 650 Resin and Hardener together and fill the syringe

- Heat the repair area with a propane torch (a heat gun will work) up to 180–220°F to dry out the repair area

- Fill the seams and rivets in this area while the aluminum is still warm

Bonding to Dissimilar Materials

G/flex is ideal for bonding a variety of materials, including dissimilar ones. It has a superior grip so that it can be used to bond to metals, plastics, glass, masonry, and fiberglass. This epoxy is ideal for repairs to aluminum boats and polyethylene and ABS canoes and kayaks. It can also be used to wet out and bond fiberglass tapes and fabrics.

Using G/flex

G/flex is a simple two-part epoxy system. Resin and hardener are mixed in a 1-to-1 mix ratio by volume. It provides a relatively long open working time, yet it cures quickly and can be used in cool temperatures. Because it is simple to mix and use, this 2-part epoxy is an excellent starting point for customers new to epoxy use.

Bonding Types

We often simplify adhesive bonds into two categories; primary and secondary or chemical and mechanical bonds. Primary bonds occur when epoxy is applied to a previously applied layer of epoxy that has not been fully cured. The layers of adhesive will bond as if they were applied at the same time and mixed together. Mechanical bonds rely on the adhesion of the epoxy to a substrate. To visualize this, imagine the epoxy flowing into all of the imperfections and the sanding scratches of the substrate and locking into place. In reality, the forces are much more complex and beyond the scope of this article.

The fundamentals of achieving strong secondary bonds are the same whether the interatomic forces are understood or not. They include:

- Wet out the substrate. The epoxy must be able to flow and wet the surface. Surface contaminates can prevent this from happening.

- Let the epoxy cure in place. Clamps must remain in place and the joint can not be stressed until the epoxy cures.

- Use a high-strength epoxy. WEST SYSTEM® epoxy is a structural adhesive after it has been cured.

Tensile Adhesion of G/flex Epoxies

Tensile stress on an adhesive is created when a load is applied perpendicular to the surface. The stress generated by the load may cause an adhesion failure that is much lower than the actual tensile strength of the glue. Tensile adhesion value is not the same as tensile strength. WEST SYSTEM epoxy is formulated to have high tensile strength for applications such as creating a strong fiberglass laminate, and high tensile adhesion to common substrates for strong bonds. WEST SYSTEM G/flex® is formulated to achieve the highest adhesion values.

WARNING: This product can expose you to chemicals which are known to the State of California to cause cancer, birth defects or other reproductive harm. For more information go to P65Warnings.ca.gov.

✔ Verified Reviews

Safe payment on our website

- Choosing a selection results in a full page refresh.

- Opens in a new window.