Product Description

#205 Fast Hardener, 7 oz (205-E)

Model # 318360

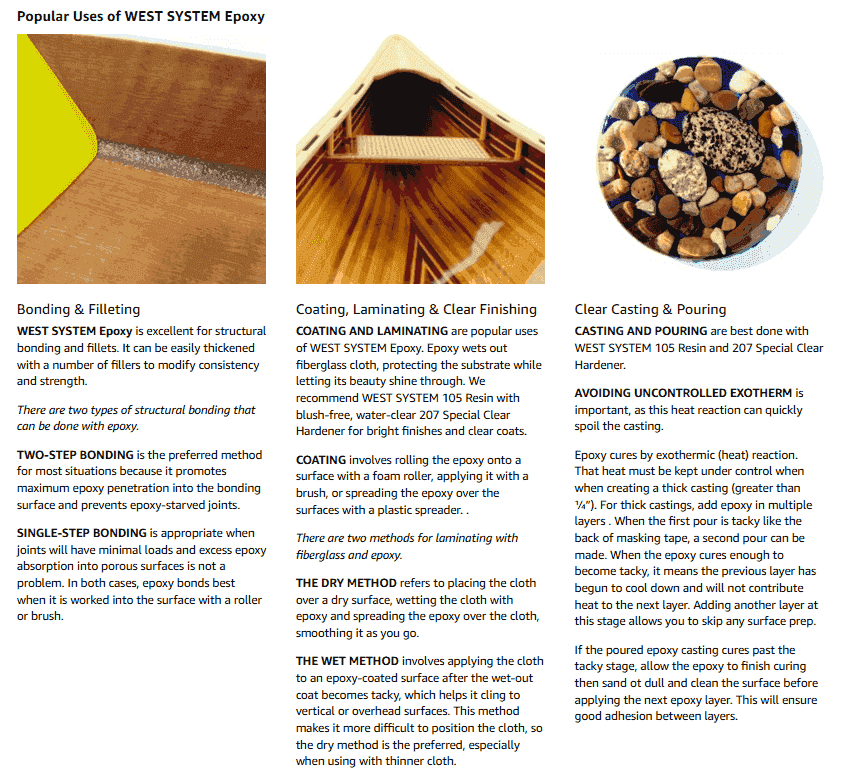

205 Fast Hardener® is formulated for general coating and bonding applications at lower temperatures and to produce a rapid cure that develops its physical properties quickly at room temperature. The 105 Epoxy Resin®/205 Fast Hardener system forms a high-strength, moisture-resistant solid bond with excellent bonding and barrier coating properties. The mix ratio is 5 parts resin to 1 part hardener by volume. Not intended for clear coating. (205E)

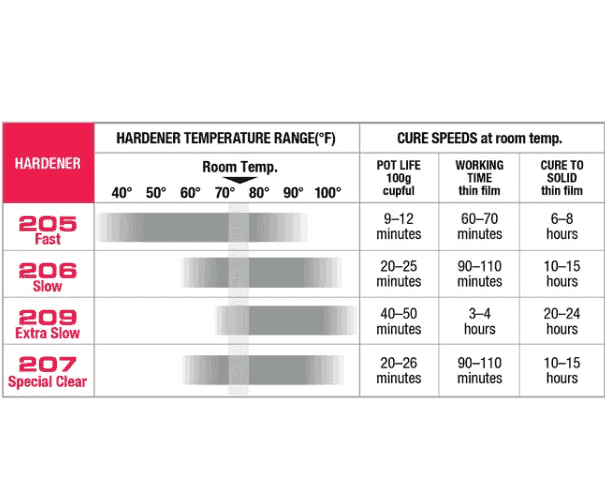

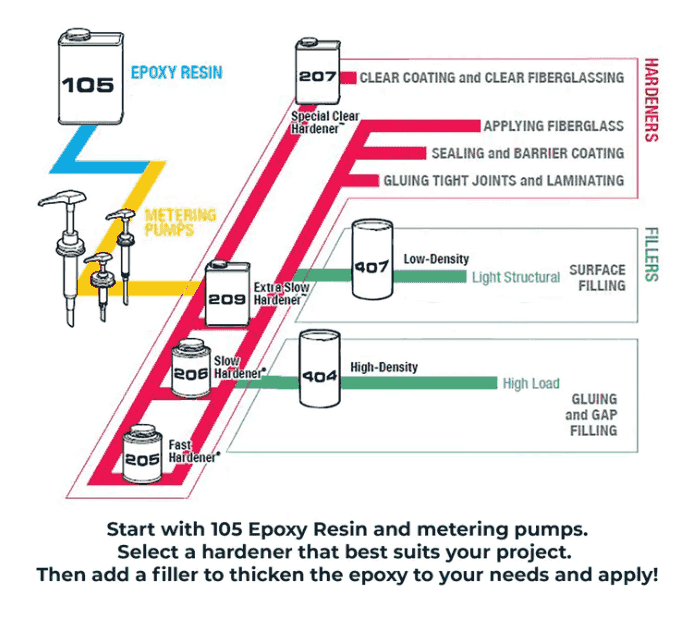

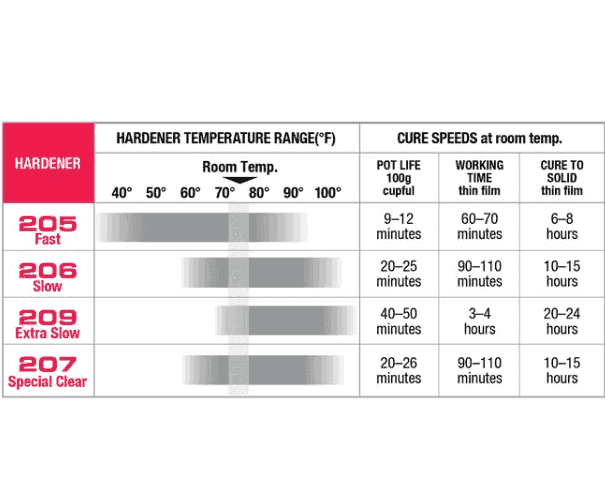

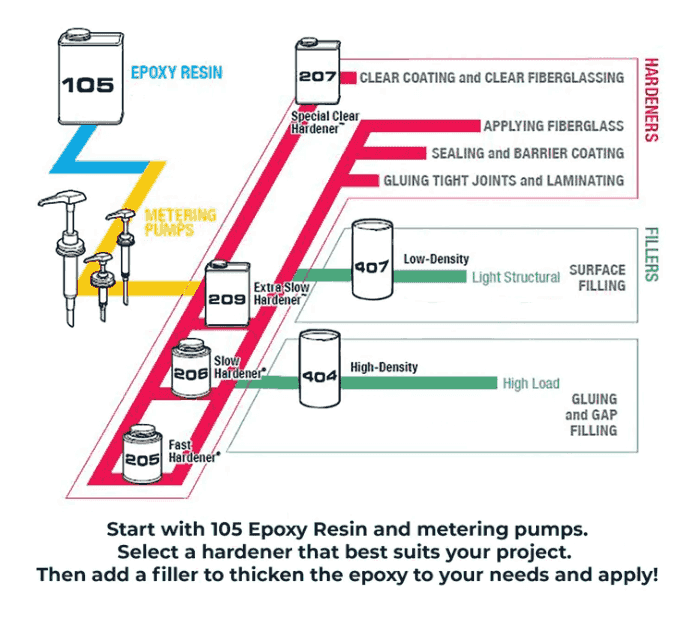

Choose the right hardener to control the cure time of 105 Epoxy Resin at the temperature at which you will work.

Select your hardener to give you the pot life you want at the temperature and conditions in which you will work. #205 Fast Hardener, mixed at a 5:1 ratio with #105 Resin, results in a pot life of 9-12 minutes at 72°F, with solid cure in 6-8 hours.

It has a minimum recommended working temperature of 40°F. #206 Slow Hardener, mixed at the standard 5:1 ratio with #105 Resin, has a 20-25 minute pot life at 72°F with 12-18 hours required for solid cure. It has a minimum recommended working of temperature of 60°F. 209 Extra Slow Hardener, mixed at a 3:1 ratio with #105 Resin, results in a pot life of 20-25 minutes at 72°F, with 10-15 hours required for a solid cure.

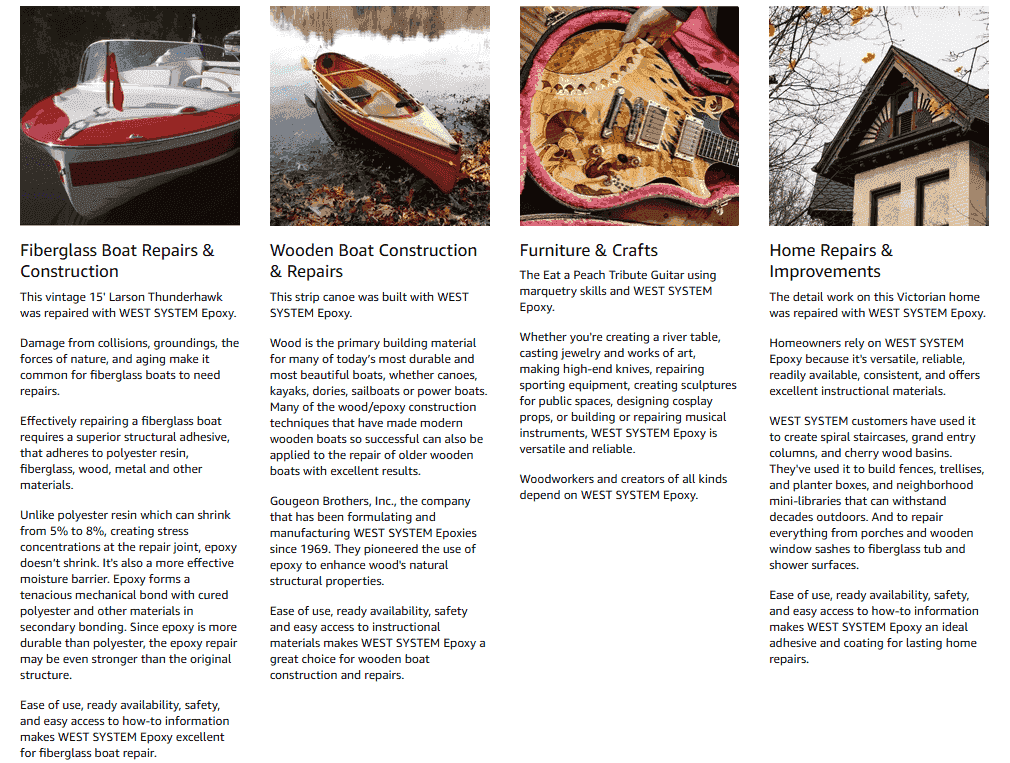

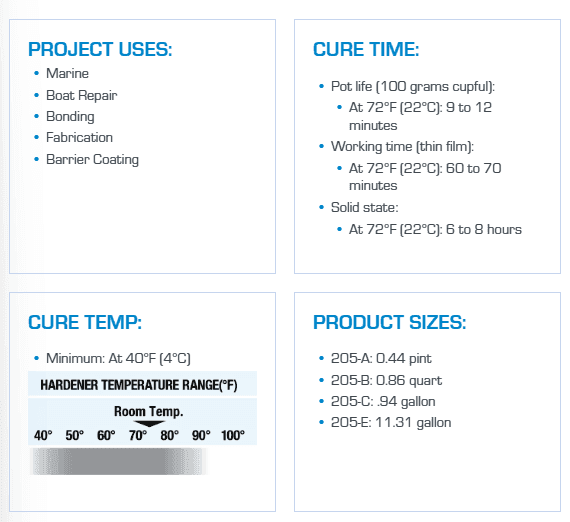

PROJECT USES

- Marine

- Boat Repair

- Bonding

- Fabrication

- Barrier Coating

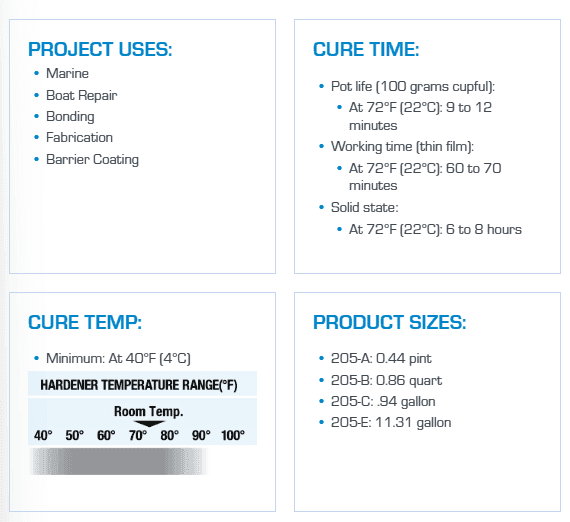

CURE TIME

- Pot life (100 grams cupful):

- At 72°F (22°C): 9 to 12 minutes

- Working time (thin film):

- At 72°F (22°C): 60 to 70 minutes

- Solid state:

- At 72°F (22°C): 6 to 8 hours

CURE TEMP

- Minimum: At 40°F (4°C)

SIZES

- 205-A: 0.44 pint (7oz)

- 205-B: 0.86 quart

- 205-C: .94 gallon

- 205-E: 11.31 gallon

DETAILS

- Best Use: Fast Hardener for West System Epoxies

- Capacity: 7 oz

- Cure Time: 6 to 8 Hours (Pot Life: 9 to 12 Minutes)

- Type: Hardener

INCLUDES

- (1) 7 oz Fast Hardener

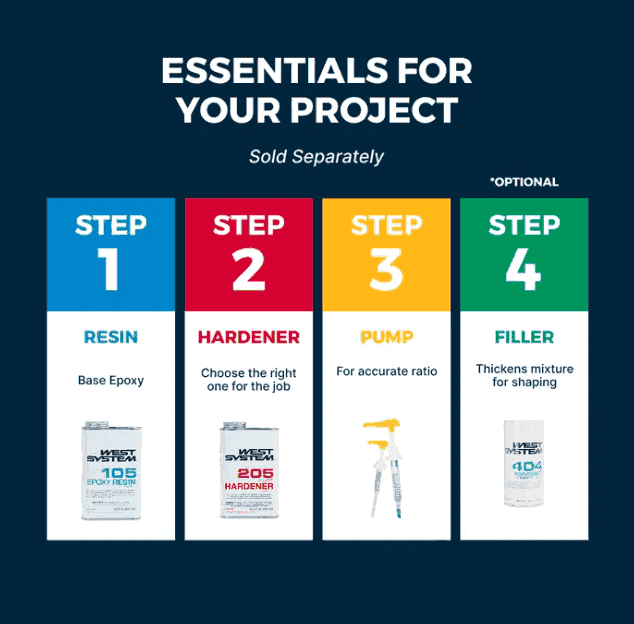

All other WEST SYSTEM products are sold separately.

For the suitability of fillers for specific applications, see the Filler Selection Chart.

For more about 105 Epoxy Resin and the complete line of WEST SYSTEM products, see the Product Selection Guide.

Additional Info:

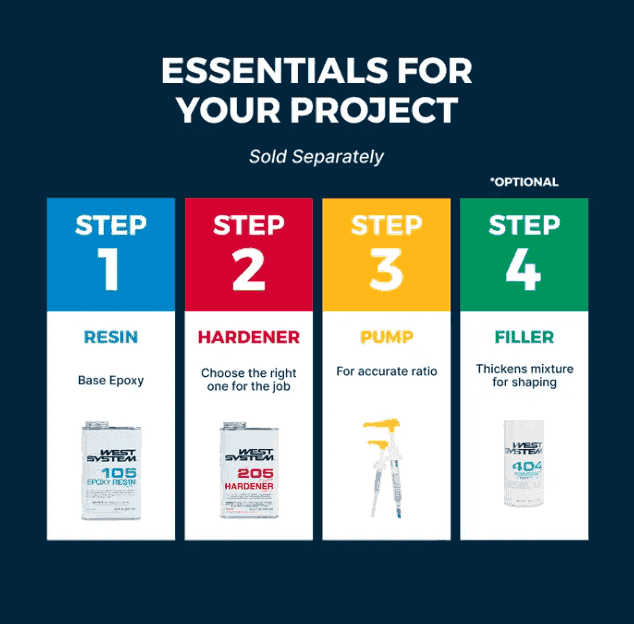

Choosing the Right Epoxy System

WEST SYSTEM® 105 Epoxy is a professional quality, two-part epoxy system developed for high strength and good versatility. The Epoxy Selection Guide is a handy tool to help you pair 105 Epoxy Resin® with a choice of four hardeners to best match your working temperatures, desired cure speed, and coating clarity.

Estimating Coverage for Fabric Application

Estimating how much epoxy is required to wet out fabric is based on the fabric weight and square footage. We provide estimates of the amount of epoxy needed to apply 1 sq. ft. of fiberglass cloth.

Pre-Warm the Resin and Hardener

Cold temperatures increase an epoxy’s viscosity, making it harder to dispense, mix and apply. Warming resin and hardener reduces their viscosity so they flow easily through their dispensing pumps. To pre-warm, place the resin and hardener containers under a warming lamp or in a warm-water bath. Pre-warmed resins and hardeners will not cling as much to your mixing equipment. They’ll also blend more easily, ensuring thorough mixing. A warmer, lower-viscosity mixture flows smoothly during application and readily penetrates porous surfaces.

Dispensing & Mixing Epoxy Cold Temperatures

Always dispense 105 Resin and 205 Fast Hardener at the proper mixing ratio. Never alter the amount of hardener because this can seriously compromise the epoxy’s ultimate strength. WEST SYSTEM 300 Mini Pumps come ready to dispense the correct ratio of resin and hardener. One full pump stroke of resin for every one full pump stroke of hardener is all you need to remember. Remember, cold epoxy resin and hardener are thicker and more difficult to pump. If you can’t pre-warm the resin and hardener, do not force the dispensing pumps up or down. Keep a steady pressure on each pump.

Gradually make a full pump stroke downward, then let rise all the way up on its own. When working with cold epoxy, give the pump head much more time to return to the top of the stroke. Dispense the epoxy into a smaller diameter pot. This will increase the chemical reaction between resin and hardener. This is because a small pot has less surface area, which prevents heat from dissipating too quickly. Stir the resin and hardener thoroughly for at least 2 minutes in a small pot. Scrape the sides and bottom of the pot. Use a mixing stick shaped to reach the pot’s corners.

Preparing Surfaces

Between applying coats of epoxy, prepare the cured epoxy surfaces. Surface prep does not need to be performed between coats of epoxy if the surface is still tacky. Cured epoxy can sometimes have a waxy/greasy film on the surface called amine blush. Remove this byproduct of the curing process before you apply the next coat of epoxy. Amine blush is easy to wash away with plain water and a 3M Scotchbrite pad. Don’t let the water evaporate. Dry the surface with plain white paper towels. Don’t use rags, because they can contaminate the surface with laundry softeners and anti-cling ingredients. The surface should then be sanded with 80-120 grit sandpaper after removing the blush. Finally, sand any remaining glossy areas with medium-grit sandpaper.

Allow the Epoxy Extra Time to Cure

Allow the epoxy additional time to cure before you remove clamps or stress the joints. As a general rule, double the cure time for every 18°F (10°C) drop in temperature. Allow even more cure time when for bonding pre-stressed joints, bent laminations, or joints that will undergo high loads. Elevate the temperature of the partially cured epoxy. This can help the resin and hardener complete their cross-linking. It’s a good way to boost the epoxy’s physical properties, even after a week at cold temperatures. To prevent thermal shock, elevate the temperature of the epoxied surface gradually. Although any temperature increase will improve cross-linking, for best results, boost the temperature to 72°F (22°C) or warmer. Final cure time depends on the hardener speed and the temperature the epoxy is exposed to. Generally, higher temperatures require shorter cure times. When applying heat to cure epoxy, don’t exceed 120°F (60°C). Leave clamps in place until the epoxy has cooled.

Metering Pumps

For group sizes "A", "B" and "C", 205 and 206 Hardeners are mixed with 105 Epoxy Resin in a ratio of 5:1. 207 and 209 Hardeners are mixed with 105 Epoxy Resin in a ratio of 3:1. To make sure you get the proportions right, we highly recommend purchase of the 300 Mini-Pump Kit, which meters the hardener and resin in the exact proportions you need. For group size "E" and larger sizes, we suggest use of either the 306-23 Special Purpose Resin/Hardener pump (Model 128845), which dispenses hardener and 105 Epoxy Resin at a ratio of 3:1, or the 306-25 Special Purpose Resin/Hardener pump (Model 335703), which dispenses hardener and 105 Epoxy Resin at a ratio of 5:1.

Instruction Manuals

Gougeon Brothers, Inc. offers a range of detailed epoxy instruction manuals to help you get started with WEST SYSTEM Epoxy products. All of our print publications are available as free downloads. Download Instruction Manuals

Epoxy Safety is Important

Epoxy is a chemical product and should be handled with care. Whether you’re a new user of WEST SYSTEM Epoxy or an old hand at it, you’re always better off with the most up-to-date information on using epoxy safely. We strive to make it easy for our epoxy customers to find our Safety Data Sheets and learn the best practices for using epoxy safely.

Epoxy Shelf Life & Proper Storage

WEST SYSTEM resins and hardeners do not have a strict shelf life. Certain changes may make them less effective for some jobs, but the resin and hardener will still be reactive. Because we are an ISO 9001 company, lot numbers are provided on containers and we keep retains of every batch we make up to 2 years from the date of manufacturing. However, the actual shelf life is typically far longer.

Shop with Confidence! Official WEST SYSTEM Dealer

- Guaranteed Authentic Products

- Factory-Fresh Inventory

- Backed by Manufacturer Support

WARNING: This product can expose you to chemicals which are known to the State of California to cause cancer, birth defects or other reproductive harm. For more information go to P65Warnings.ca.gov.

✔ Verified Reviews

Safe payment on our website

- Choosing a selection results in a full page refresh.

- Opens in a new window.