Product Description

#206 Slow Hardener, 7 oz (206-A)

Model # 326082

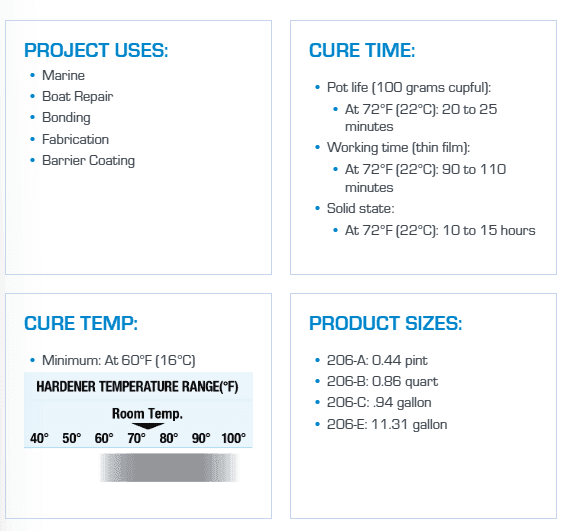

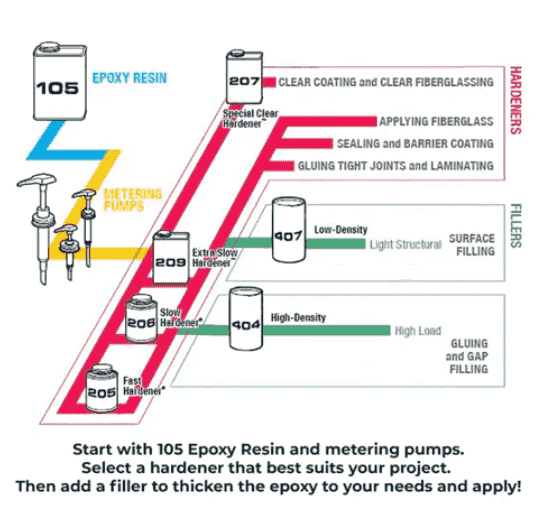

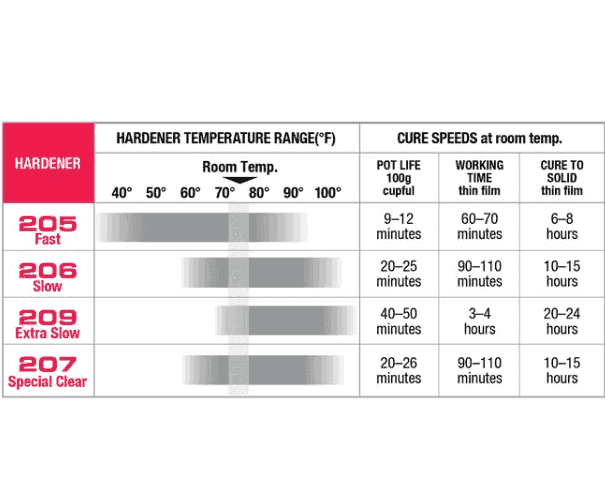

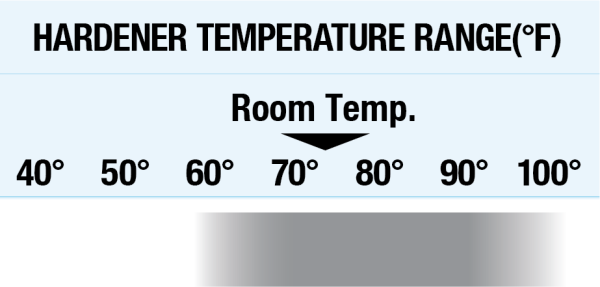

Choose the right hardener to control the cure time of 105 Epoxy Resin at the temperature at which you will work.

206 Slow Hardener® is a low-viscosity epoxy curing agent for use when extended working time or a longer cure time is needed. It also provides adequate working time at higher shop temperatures. When combined with 105 Epoxy Resin® in a five-part epoxy resin to one-part hardener ratio, the cured 105 Epoxy Resin/206 Slow Hardener mixture yields a rigid, high-strength, moisture-resistant solid bond with excellent bonding and barrier coating properties. The mix ratio is 5 parts resin to 1 part hardener by volume. 206 Slow Hardener is not intended for clear coating. (206A)

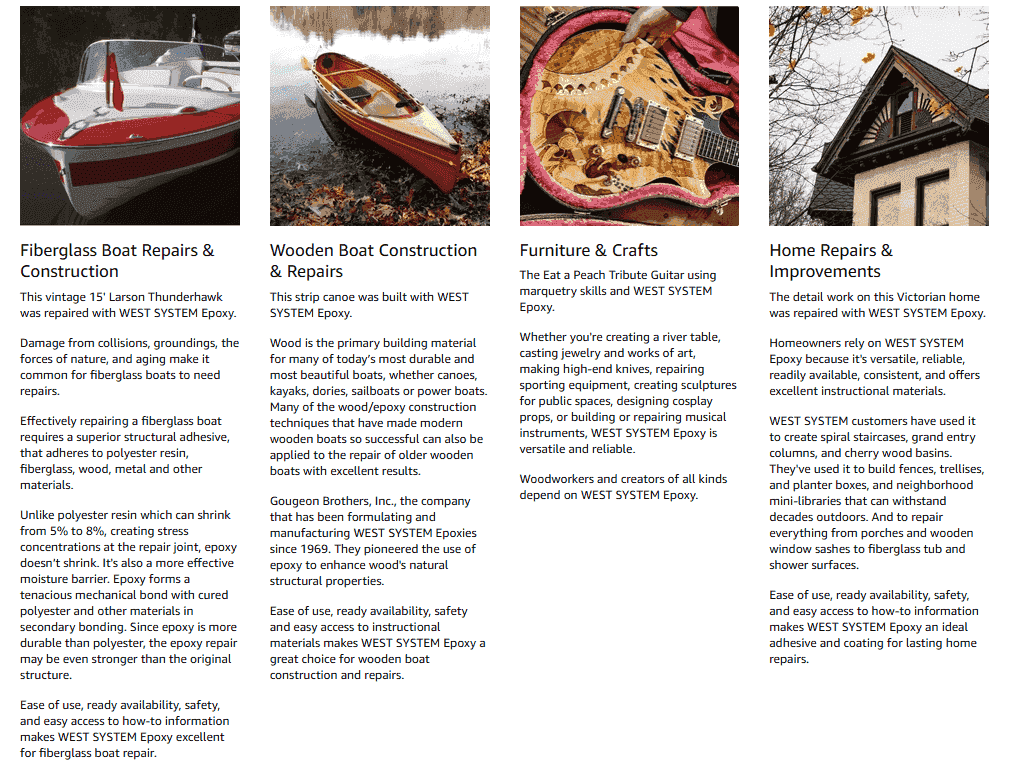

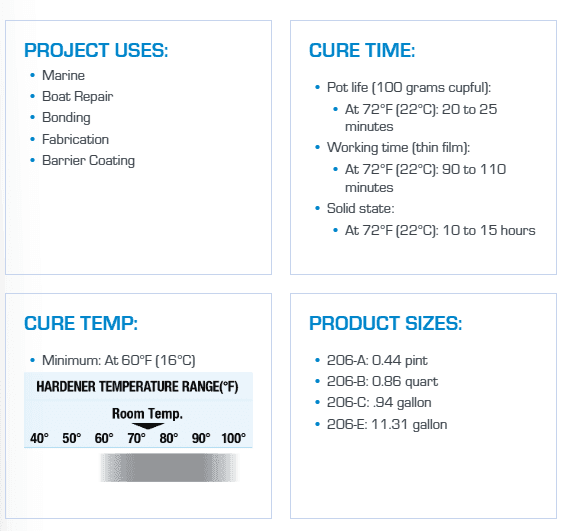

PROJECT USES

- Marine

- Boat Repair

- Bonding

- Fabrication

- Barrier Coating

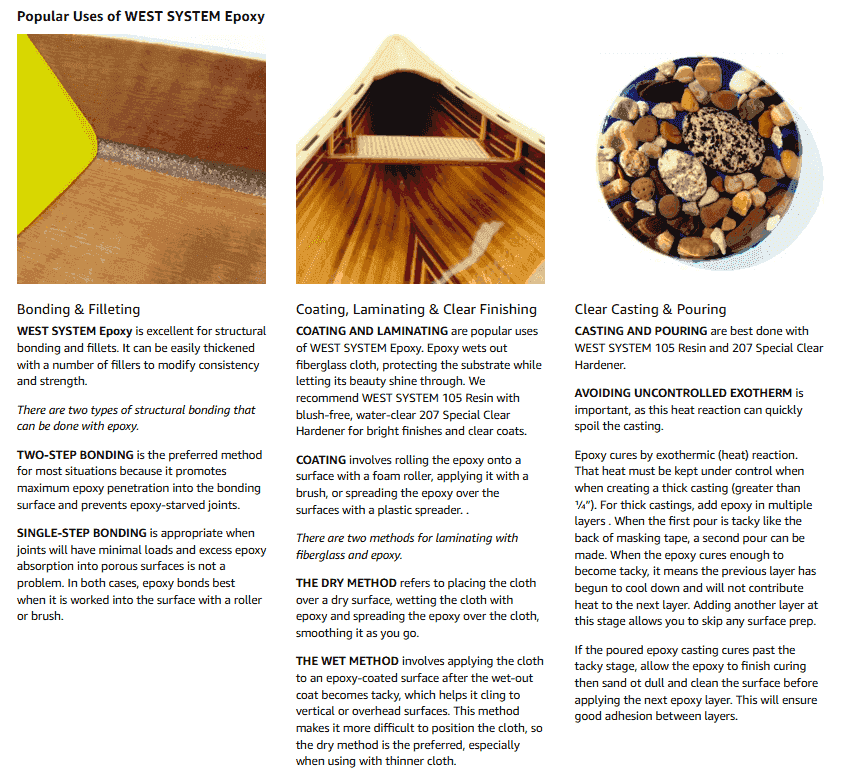

CURE TIME

- Pot life (100 grams cupful):

- At 72°F (22°C): 20 to 25 minutes

- Working time (thin film):

- At 72°F (22°C): 90 to 110 minutes

- Solid state:

- At 72°F (22°C): 10 to 15 hours

CURE TEMP

- Minimum: At 60°F (16°C)

SIZES

- 206-A (7 oz)

- 206-B (27.5 fl. oz)

- 206-C (121 fl. oz)

- 206-E (11.31 gallon)

DETAILS

- Best Use: Slow Hardener for West System Epoxies

- Capacity: 7 oz

- Cure Time: 10 to 15 Hours (Pot Life 20 to 25 Minutes)

- Type: Hardener

INCLUDES

- (1) 7 oz Slow Hardener

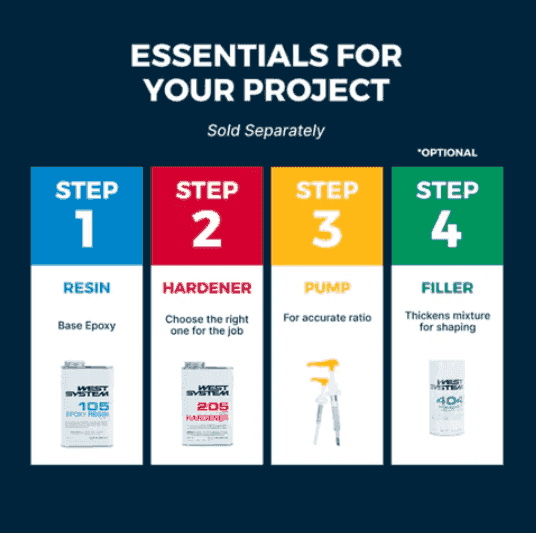

All other WEST SYSTEM products are sold separately.

For the suitability of fillers for specific applications, see the Filler Selection Chart.

For more about 105 Epoxy Resin and the complete line of WEST SYSTEM products, see the Product Selection Guide.

Additional Info:

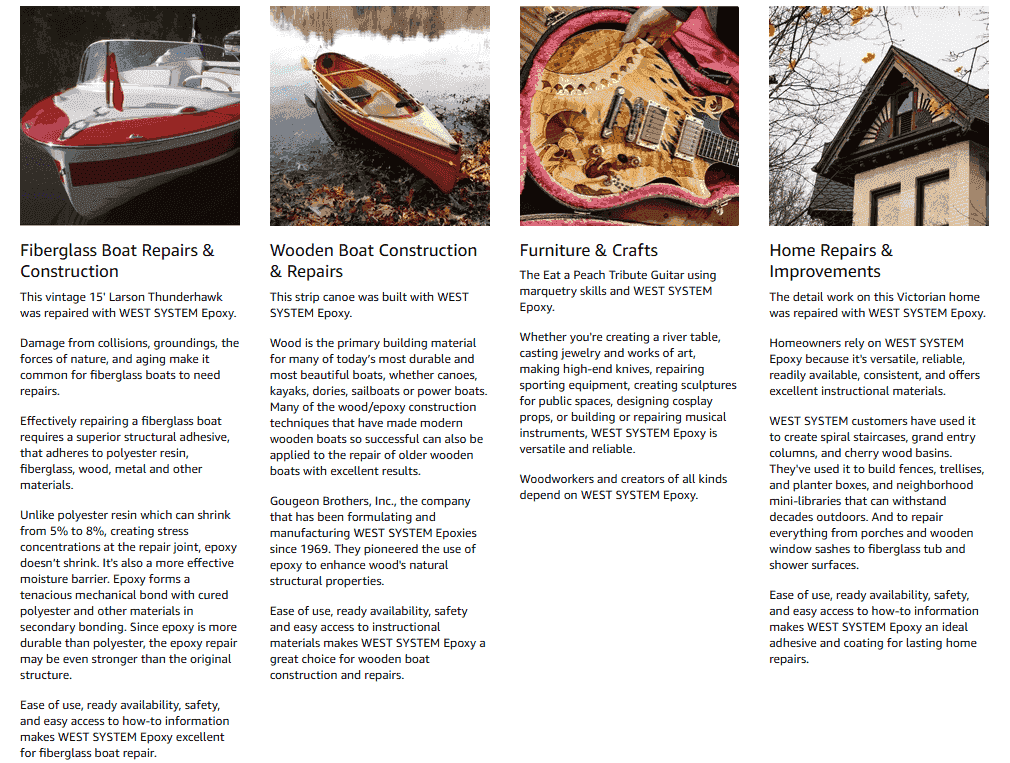

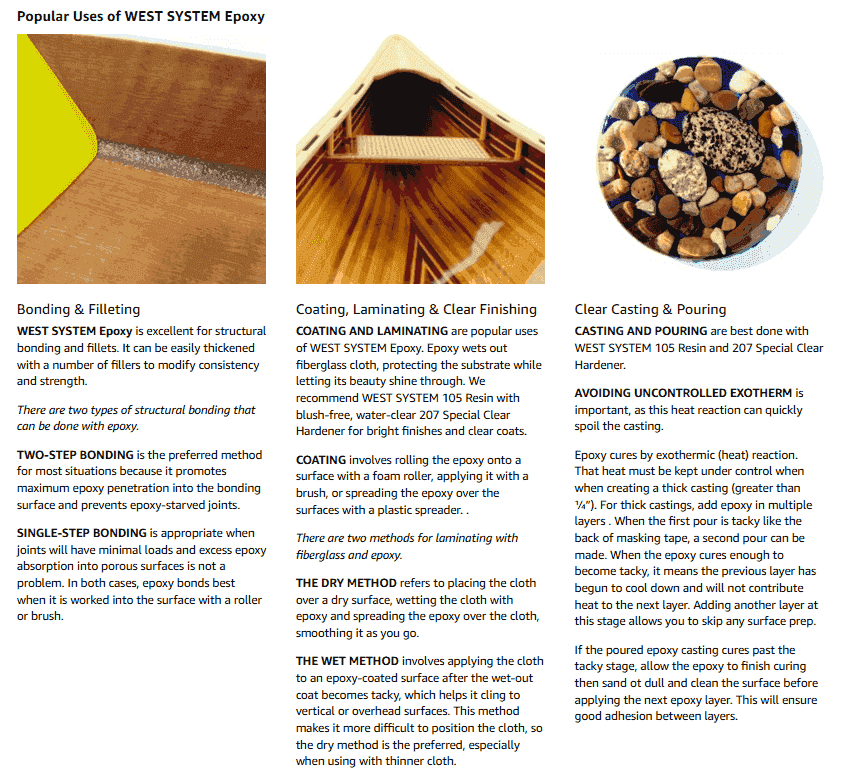

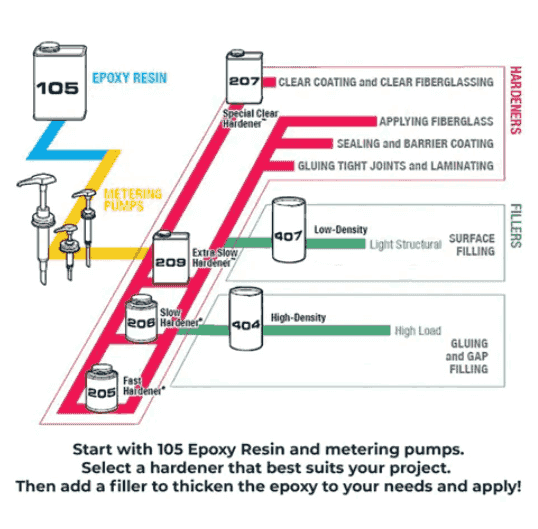

Choosing the Right Epoxy System

WEST SYSTEM® 105 Epoxy is a professional quality, two-part epoxy system developed for high strength and good versatility. The Epoxy Selection Guide is a handy tool to help you pair 105 Epoxy Resin® with a choice of four hardeners to best match your working temperatures, desired cure speed, and coating clarity.

Estimating Coverage for Fabric Application

Estimating how much epoxy is required to wet out fabric is based on the fabric weight and square footage. We provide estimates of the amount of epoxy needed to apply 1 sq. ft. of fiberglass cloth.

Dispensing & Mixing Epoxy Cold Temperatures

Always dispense 105 Resin and 205 Fast Hardener at the proper mixing ratio. Never alter the amount of hardener because this can seriously compromise the epoxy’s ultimate strength. WEST SYSTEM 300 Mini Pumps come ready to dispense the correct ratio of resin and hardener. One full pump stroke of resin for every one full pump stroke of hardener is all you need to remember. Remember, cold epoxy resin and hardener are thicker and more difficult to pump. If you can’t pre-warm the resin and hardener, do not force the dispensing pumps up or down. Keep a steady pressure on each pump. Gradually make a full pump stroke downward, then let rise all the way up on its own. When working with cold epoxy, give the pump head much more time to return to the top of the stroke. Dispense the epoxy into a smaller diameter pot. This will increase the chemical reaction between resin and hardener. This is because a small pot has less surface area, which prevents heat from dissipating too quickly. Stir the resin and hardener thoroughly for at least 2 minutes in a small pot. Scrape the sides and bottom of the pot. Use a mixing stick shaped to reach the pot’s corners.

Epoxy Pot Life vs. Working Time

The pot life listed on the WEST SYSTEM technical data sheets refers to a confined mass of 100 grams of epoxy at 72°F. Pot life is always shorter than working time because epoxy contained in a pot kicks off faster than epoxy spreads into a roller pan (thin film). Spreading out the epoxy dissipates heat, extending its working time. 206 Extra Slow Hardener TDS

Metering Pumps

For group sizes "A", "B" and "C", 205 and 206 Hardeners are mixed with 105 Epoxy Resin in a ratio of 5:1. 207 and 209 Hardeners are mixed with 105 Epoxy Resin in a ratio of 3:1. To make sure you get the proportions right, we highly recommend purchase of the 300 Mini-Pump Kit, which meters the hardener and resin in the exact proportions you need. For group size "E" and larger sizes, we suggest use of either the 306-23 Special Purpose Resin/Hardener pump (Model 128845), which dispenses hardener and 105 Epoxy Resin at a ratio of 3:1, or the 306-25 Special Purpose Resin/Hardener pump (Model 335703), which dispenses hardener and 105 Epoxy Resin at a ratio of 5:1.

Filler and Epoxy Strength

WEST SYSTEM Epoxy fillers are used to thicken the basic epoxy resin/hardener mixture for specific applications. Adding these filling agents to blended epoxy resin and hardener allows you to control the consistency of the epoxy, bridge gaps in joints, create either strong or sandable fillets with epoxy, or alter the cured density of epoxy, making it easier to sand smooth. Selecting Epoxy Fillers

No Need for Excessive Clamping Force

Unlike traditional wood glues, WEST SYSTEM 105 Resin-based epoxy mixtures including 105 Resin and 206 Slow Hardener are stronger than wood or many other substrates. Because of this, it is beneficial to have some epoxy between the objects you are gluing together. As long as the parts are held in place and epoxy is contacting the entire surface of both substrates, no clamping pressure is needed.

Instruction Manuals

Gougeon Brothers, Inc. offers a range of detailed epoxy instruction manuals to help you get started with WEST SYSTEM Epoxy products. All of our print publications are available as free downloads. Download Instruction Manuals

Epoxy Shelf Life & Proper Storage

WEST SYSTEM resins and hardeners do not have a strict shelf life. Certain changes may make them less effective for some jobs, but the resin and hardener will still be reactive. Because we are an ISO 9001 company, lot numbers are provided on containers and we keep retains of every batch we make up to 2 years from the date of manufacturing. However, the actual shelf life is typically far longer.

Shop with Confidence! Official WEST SYSTEM Dealer

- Guaranteed Authentic Products

- Factory-Fresh Inventory

- Backed by Manufacturer Support

WARNING: This product can expose you to chemicals which are known to the State of California to cause cancer, birth defects or other reproductive harm. For more information go to P65Warnings.ca.gov.

✔ Verified Reviews

Safe payment on our website

- Choosing a selection results in a full page refresh.

- Opens in a new window.