Product Description

#207 Special Clear Hardener, 1.45 gallons (207-SC)

Model # 372938

FREE Shipping

LOWEST PRICES GUARANTEED

When working with WEST SYSTEM 105 Epoxy Resin, this is the hardener to use where a clear finish is desired.

** Pair the Group Size of the hardener you choose with the correct Group Size of 105 Epoxy Resin. 207 SC-Size hardener should be paired with 105 C-Size Resin.

207 Special Clear Hardener® was developed for coating and fiberglass cloth application where an exceptionally clear, moisture-resistant, carbon fiber or natural wood finish is desired. 207 Special Clear Hardener will not blush or turn cloudy in humid conditions. Thin film applications roll out and tip off smoothly, requiring less sanding in preparation for finish coatings. The mix ratio is 3 parts resin to 1 part hardener by volume.

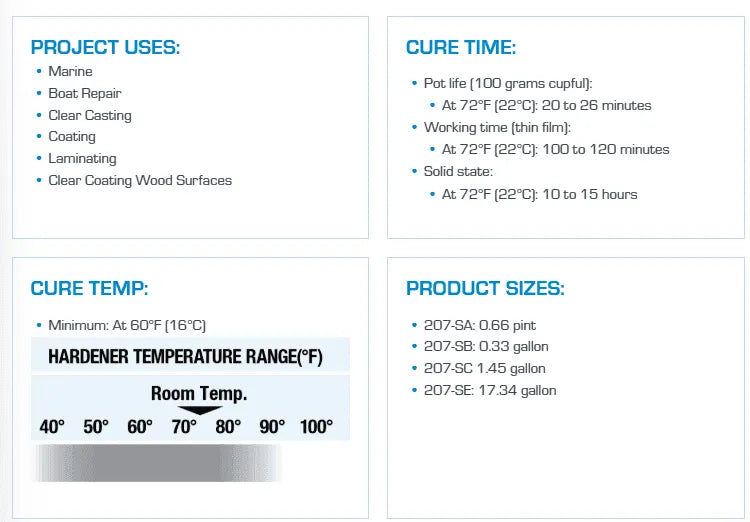

PROJECT USES

- Marine

- Boat Repair

- Clear Casting

- Coating

- Laminating

- Clear Coating Wood Surfaces

CURE TIME

- Pot life (100 grams cupful):

- At 72°F (22°C): 20 to 26 minutes

- Working time (thin film):

- At 72°F (22°C): 100 to 120 minutes

- Solid state:

- At 72°F (22°C): 10 to 15 hours

CURE TEMP

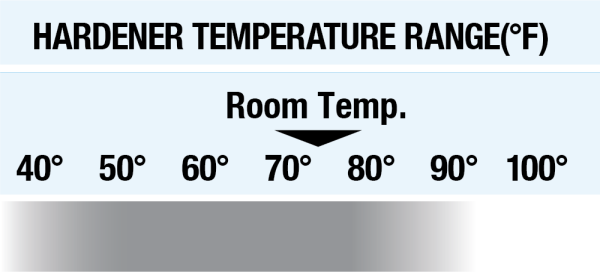

- Minimum: At 60°F (16°C)

SIZES

- 207-SA (10.6 fl. oz)

- 207-SB (42.2 fl. oz)

- 207-SC (1.45 gallon)

FEATURES

- Excellent for use in hot or humid conditions

- Produces a clear, low-blush finish

- Provides excellent adhesion for bonding applications

- Contains UV stabilization additive, but still requires long term UV protection with quality marine paint or varnish

- 300 Mini-Pump Kit recommended for Group Sizes A, B, and C

- 306-23 Special Purpose Resin/Hardener Pump (Model 128845) recommended for large quantities

Details:

- Best Use: Special Clear Non-Blushing Hardener for 105 Epoxy Resin

- Capacity: 1.45 Gallons

- Cure Time: 10 to 15 Hours (Working Time 100-120 Minutes) at 72 F

- Type: Hardener

INCLUDES

- (1) 1.45 Gallon Special Clear Hardener

All other WEST SYSTEM products are sold separately.

For the suitability of fillers for specific applications, see the Filler Selection Chart.

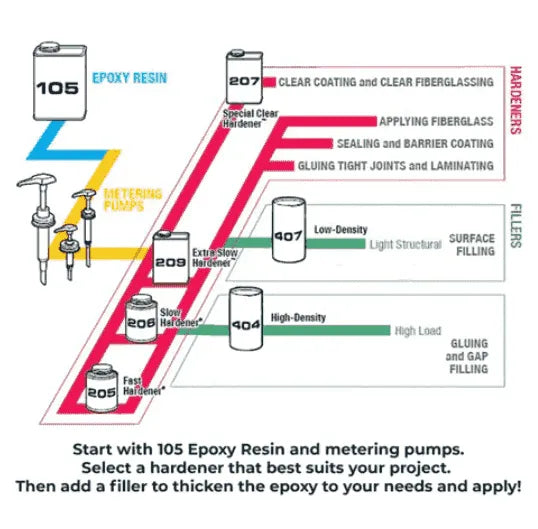

For more about 105 Epoxy Resin and the complete line of WEST SYSTEM products, see the Product Selection Guide.

Additional Info:

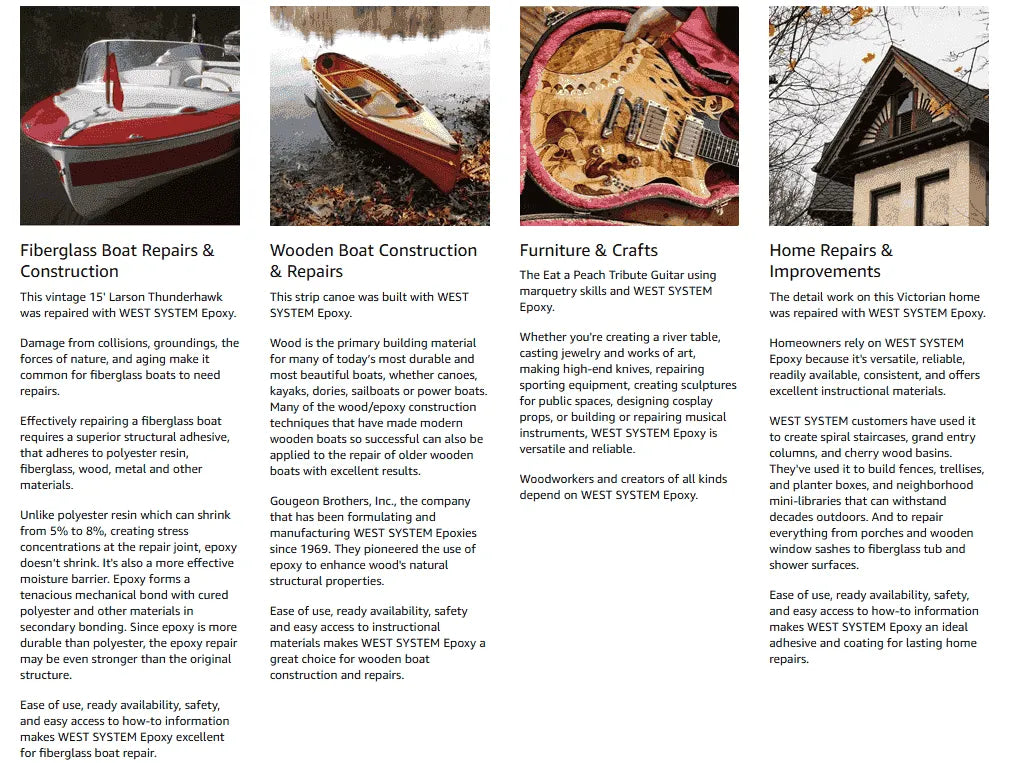

Choosing the Right Epoxy System

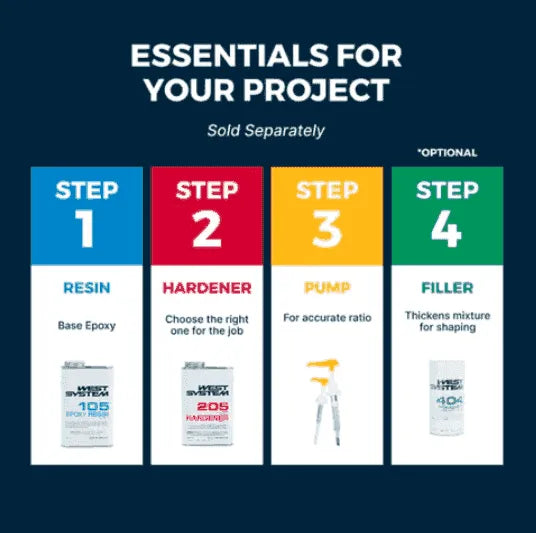

WEST SYSTEM® 105 Epoxy is a professional quality, two-part epoxy system developed for high strength and good versatility. The Epoxy Selection Guide is a handy tool to help you pair 105 Epoxy Resin® with a choice of four hardeners to best match your working temperatures, desired cure speed, and coating clarity.

Estimating Coverage for Fabric Application

Estimating how much epoxy is required to wet out fabric is based on the fabric weight and square footage. We provide estimates of the amount of epoxy needed to apply 1 sq. ft. of fiberglass cloth.

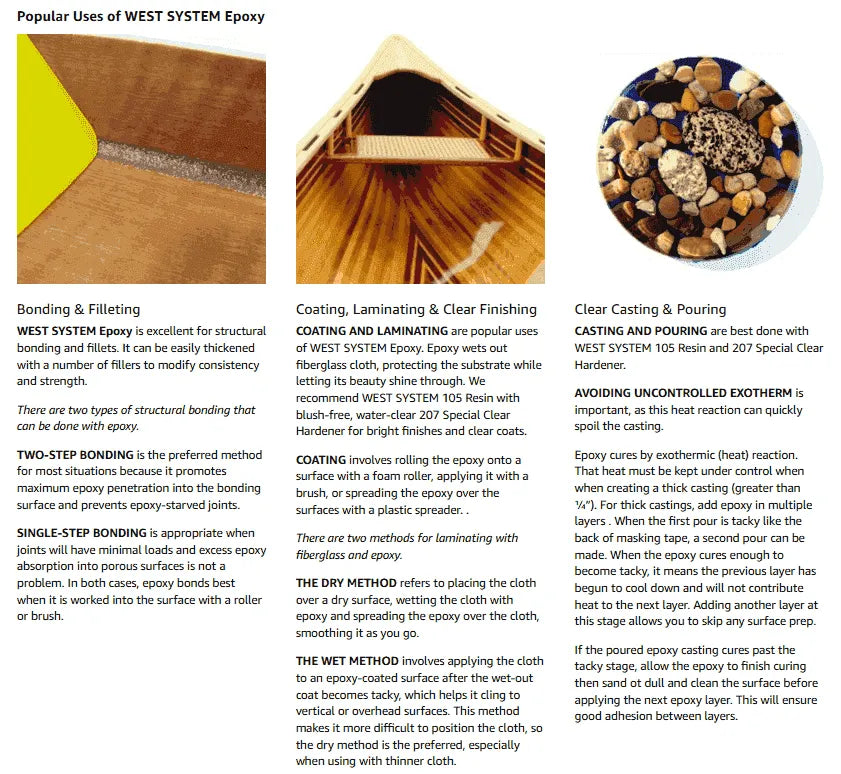

Clear Casting Table Tops with 207 Special Clear Hardener

Pouring a thick coating or casting it onto a tabletop, bar or countertop creates a popular effect. 207 Special Clear Hardener is especially well suited to these applications. A ¼” thick coating of 105 Resin and 207 Hardener is deep enough to cast objects such as memorabilia into the epoxy for decorative accents. Here is what you need to know when casting a clear epoxy coat over flat surfaces. See Casting Epoxy in Epoxyworks for more info.

Preparation for Casting 105 Epoxy Resin / 207 Special Clear Hardener

- Small, solid objects like coins, bottle caps, mosaic tiles, pebbles, guitar picks, buttons, seashells, and sea glass, are great choices for casting into a layer of epoxy.

- Photographs or postcards will darken and curl when wetted with epoxy. To prevent this, first coat them with a craft decoupage glue like Mod Podge™.

- Porous materials such as burlap can trap a lot of air bubbles.

Before you get started, dam the perimeter of the surface you plan to coat. Duct tape around the bottom edge of the surface to prevent the epoxy from dripping. For coatings ¼” thick, tack a piece of stock molding with 6 mil plastic under it around the table’s perimeter. Make sure the surface is level and the temperature of the substrate is stable before pouring epoxy. To prevent bubbles “outgassing” from the surface, brush one or two thin coats of epoxy onto the surfaces. Allow this to reach gelation (about 6 hours at room temperature) before pouring epoxy. If you wait more than 18 hours before pouring your deeper layer of epoxy, be sure to sand the seal coating before pouring the epoxy mixture. Pierce a hole in the bottom of a mixing pot. Cover this hole with duct tape. This will be your pouring vessel.

Removing Bubbles

A handheld propane torch or heat gun can be used to break the epoxy’s surface tension and help remove air bubbles. First, give the poured epoxy a couple of minutes to self-level. The bubbles should rise to the surface. Then move the heat source rapidly over the area (at roughly one foot per second) to avoid overheating the epoxy. You don’t want the heat source to make the epoxy gel or smoke.

Finish Coatings

Finish coatings like paint or varnish are applied over an epoxy barrier coat to decorate the surface and protect the epoxy from sunlight. The finish coating extends the life of the epoxy moisture barrier, which in turn provides a stable base that extends the life of the finish coating. Together the two form a protective system far more durable than either coating by itself.

Epoxy Pot Life vs. Working Time

The pot life listed on the WEST SYSTEM technical data sheets refers to a confined mass of 100 grams of epoxy at 72°F. Pot life is always shorter than working time because epoxy contained in a pot kicks off faster than epoxy spread into a roller pan (thin film). Spreading out the epoxy dissipates heat, extending its working time 207 Special Clear Hardener TDS.

Metering Pumps

For group sizes "A", "B" and "C", 205 and 206 Hardeners are mixed with 105 Epoxy Resin in a ratio of 5:1. 207 and 209 Hardeners are mixed with 105 Epoxy Resin in a ratio of 3:1. To make sure you get the proportions right, we highly recommend purchase of the 300 Mini-Pump Kit, which meters the hardener and resin in the exact proportions you need. For group size "E" and larger sizes, we suggest use of either the 306-23 Special Purpose Resin/Hardener pump (Model 128845), which dispenses hardener and 105 Epoxy Resin at a ratio of 3:1, or the 306-25 Special Purpose Resin/Hardener pump (Model 335703), which dispenses hardener and 105 Epoxy Resin at a ratio of 5:1.

Instruction Manuals

Gougeon Brothers, Inc. offers a range of detailed epoxy instruction manuals to help you get started with WEST SYSTEM Epoxy products. All of our print publications are available as free downloads. Download Instruction Manuals.

Epoxy Safety is Important

Epoxy is a chemical product and should be handled with care. Whether you’re a new user of WEST SYSTEM Epoxy or an old hand at it, you’re always better off with the most up-to-date information on using epoxy safely. We strive to make it easy for our epoxy customers to find our Safety Data Sheets and learn the best practices for using epoxy safely.

Epoxy Shelf Life & Proper Storage

WEST SYSTEM resins and hardeners do not have a strict shelf life. Certain changes may make them less effective for some jobs, but the resin and hardener will still be reactive. Because we are an ISO 9001 company, lot numbers are provided on containers and we keep retains of every batch we make up to 2 years from the date of manufacturing. However, the actual shelf life is typically far longer.

Shop with Confidence! Official WEST SYSTEM Dealer

- Guaranteed Authentic Products

- Factory-Fresh Inventory

- Backed by Manufacturer Support

WARNING: This product can expose you to chemicals which are known to the State of California to cause cancer, birth defects or other reproductive harm. For more information go to P65Warnings.ca.gov.

✔ Verified Reviews

Safe payment on our website

- Choosing a selection results in a full page refresh.

- Opens in a new window.